Kilmore House

Improving Efficiency,

Extending Product Life Cycles,

Reducing Carbon Footprint.

The refurbishment of Kilmore House represents a benchmark in modernising commercial spaces without disrupting daily operations. Tasked with this ambitious project, design engineering firm Baker O’Reilly specified Diffusion Fancoils, which were installed by Lynskey Engineering enhancing the building’s HVAC efficiency and tenant comfort.

In particular, the upgrading of existing Diffusion Fancoils on occupied floors, with the installation of the latest energy efficient EC motor fandecks with market-leading low SFP required careful coordination, minimising disruption while delivering long-lasting climate control improvements. They also took the opportunity to install new heating and cooling coils which are optimised to work efficiently with low temperature hot water provided by heat pumps, thereby future proofing for the next phase of the development.

Energy Efficient SFP Fancoils

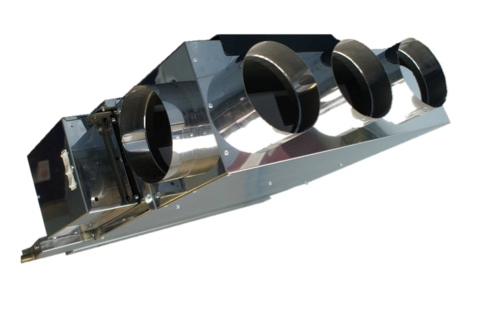

We successfully supplied Baker O’Reilly Engineering and Lynskey Engineering with Diffusion Energy Saving 270 Fancoils, known for their industry-leading Specific Fan Powers (SFPs). These units are designed to optimise energy efficiency, providing a superior balance of performance and sustainability. By incorporating these advanced fancoils, both engineering teams can deliver enhanced air quality and reduced operational costs for Kilmore House, ensuring a high standard of comfort and efficiency for all building occupants.

Benefits of Refurbishing Existing Diffusion Fancoils

On floors with existing tenants Baker O’Reilly specified that fan decks within existing fancoils were replaced in order to minimise disruption. This also offered a range of benefits that significantly enhance both energy efficiency and indoor comfort.

We supplied and Lynskey Engineering installed new EC fan decks with low SFPs and replacement heating & cooling coils for the existing Diffusion fancoil units.

The controls on the FCUs were also upgraded in order for the units to work with the new highly efficient EC fan decks.

- Lowers the carbon footprint of any refurbishment by using existing equipment.

- Improving energy efficiency, using the latest EC motor and heating & cooling coil design technology to reduce energy consumption while delivering design airflow.

- Improved airflow control allows for better temperature control, enhancing comfort across all occupied spaces.

- In the long term, these replacements lower operational costs and extend the life of the HVAC system, making it a smart investment.

- Future proofs the HVAC equipment for the installation of energy efficient heat pumps at a later date.

This is a fine example of how refurbishing existing buildings, by upgrading original equipment (Diffusion Fancoils) not only reduces costs, can also reduce carbon footprint and therefore reduce our environmental impact.

Questions?

At Keane Environmental Ltd., we understand that every job, large or small, has its own challenges. We’d be delighted to work with you to find the correct solution for your building. If you’d like to hear more about this or any of our other projects, contact us today.

Consulting Engineers: Baker OReilly

Mechanical Contractors: Lynskeys Engineering

Suppliers: Keane Environmental Ltd.