The Road to Net Zero

On the road to Net Zero

How Kampmann are progressing with the upcoming challenges.

Prepared for Change

It ́s fair to say, that the construction industry has seen more changes within the last year than the 20 years before. These days we all talk about “Net Zero Carbon Buildings”, “Decarbonization” and “Embodied Carbon”.

To achieve the targets set within the Paris Climate Agreement we all have to change the way we live, but also the way we design and build the buildings we live and work in. Of course these buildings need to be comfortable for the occupants with regards to internal room temperatures, fresh air supply and noise levels, but we also have to look into the electrical and thermal energy consumption and the materials and components we will use.

As a leading and experienced manufacturer within Trench Heating/Cooling and Ventilation Technology,

Kampmann are now in a position to share some ideas, developments and new products, that complement the changes we have seen in the last year.

Part L

One of the most significant changes we have seen are the updated

carbon factors for electricity within Part L 2020. Bringing an end

to the use of fossil fuels to thermally condition our buildings. We now expect our buildings to be cooled and heated on the basis of clean electrical energy in the future.

Embodied Carbon

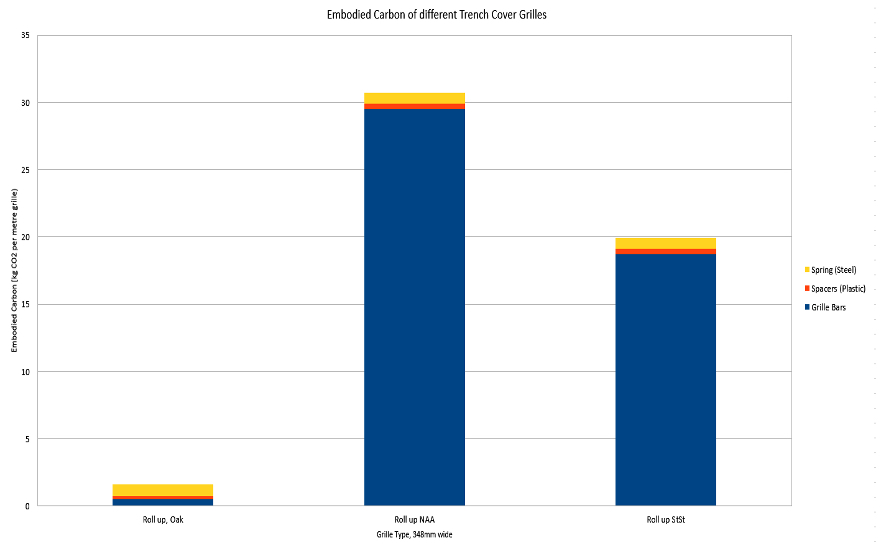

Another significant change specially within the HVAC industry is the publication of the CIBSE TM65 focusing on the embodied carbon of HVAC products. It is not only about the operational carbon to condition our buildings. The embodied carbon of the products and materials we use needs to be considered. Manufacturers will have to provide Environmental Product Declarations (EPDs) for their complete product portfolio. From a manufacturer’s perspective, we can say, that this is a massive requirement, but we appreciate, that this is the only way to go. This is not only collecting the data for existing products, this will also change the way manufacturers will use materials for their newly developed products.

All Kampmann trench products come with a covering grille on top. These days on most projects, these grilles are made of aluminium, as this is the most commercial option. We all know, that looking from an embodied carbon perspective, the use of aluminium is most critical. Therefore, there are alternative materials for grilles available. Changing from aluminium grilles to stainless steel grilles will reduce the embodied carbon of the grille by about -30%. Even way more significant, changing from an aluminium grille to a wooden/timber grille, will reduce the embodied carbon of the grille by about -90%.

Low SFPs

Trench Technology is a proven solution to heat, cool and ventilate our buildings. The coils within the units have been optimised to work with ultra-low LPHW temperatures fed by heat pumps and cooled with chilled water, both wet and dry cooling. All these units come with modern EC-fan technology. This allows the trench units to run on lowest noise levels, even down to NR 25. In addition, modern trench units achieve Specific Fan Power levels (SFPs) in the region of 0,08 to 0,12 watts per l/s.

The New Generation

A new generation of Trench Heating and Cooling units combines direct electrical heating and a reduction in embodied carbon. Kampmann has developed a heating and cooling trench, that works with chilled water cooling and direct electrical heating. Direct electrical heating from renewable, fossil free sources will be on the rise in the future and can be used for heating in our Net-Zero Buildings. Obviously, these do not require LPHW pipe connections. Therefore, the complete LPHW pipework within the floors and risers can be reduced significantly if not omitted completely. It is not only the pipework itself, it also includes the lagging, associated valves and actuators, as well as fittings and fixings. This will have a direct impact on the embodied carbon calculations of the building, as a significant amount of material will not be required at all. To complete this, units with direct electrical heating do not require the effort in commissioning as with LPHW heating. This all leads in savings within installation time, as well as cost savings associated with the reduction of materials/components needed and reduction in labour time.

Decentralization

During the pandemic many office buildings were only partly occupied, raising the question why should we heat, cool and ventilate our complete buildings when they are only partly in use? New decentralized solutions for conditioning our spaces make a flexible use possible, as only occupied areas will be heated, cooled and ventilated. This will come with high energy savings, as energy is only used where needed.

Decentralized room conditioning units have become a proven solution in Continental Europe, so why not use this technology in Ireland also?

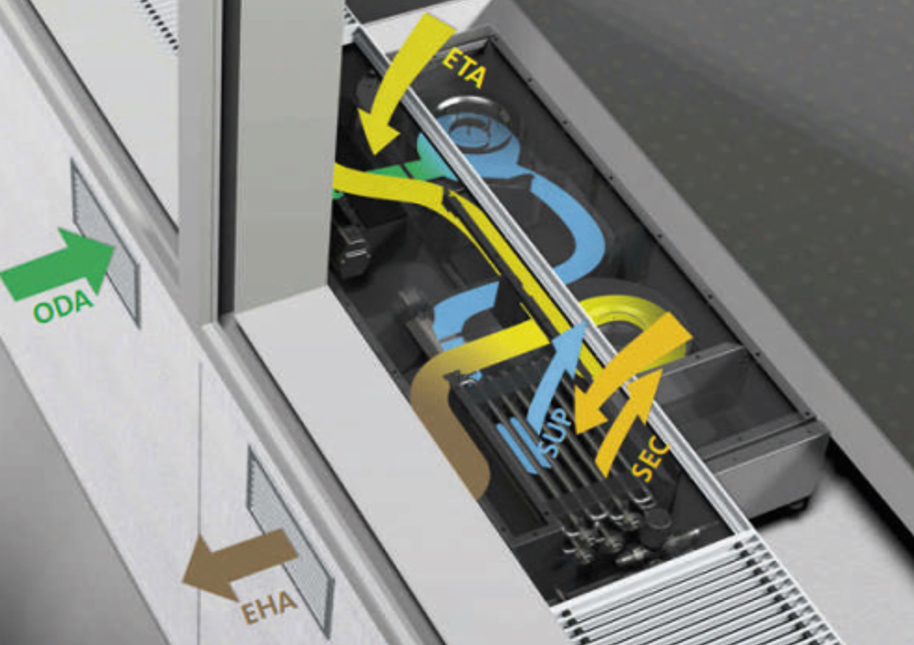

The optical appearance of a modern decentralized room conditioning unit is the same as with all other trench units. A box in the floor with a grille on top. Within a commercial space for example, Kampmann suggest to install one unit per façade grid. This will give maximum flexibility within the space, as room partitioning walls can be placed on the façade grids or changed at a later stage. Different with these units is, that each unit has two penetrations through the façade to the outside, one as an air intake, the other one for extract air. A plate heat exchanger for heat recovery it fitted within the units.

Therefore, the decentralized room conditioning units come with the following functions:

- Outside air supply into the room via a modern EC fan, motorized damper and F7 filter,

- Extract of waste air to the outside, also via a modern EC fan,

- Heat recovery of both above air flows via a cross flow plate heat exchanger,

- Chilled water cooling and/or LPHW heating,

- Recirculation heating/cooling via an additional cross flow fan within the unit.

A decentralized use of units like this will come with energy savings compared to central systems as only units within occupied areas are switched on. All the others are turned off and do not need energy.

Net Zero – A Problem or An Opportunity?

We are all on the road to “Net Zero” – in our private life, as well as in our business life. For both we all will need buildings, that are designed to achieve a comfort level with regards to fresh air supply, temperature and acoustics. It is up to manufacturers in our market to develop products that allow this comfort level to a achieved, but also support the “Net Zero” requirements.

Manufacturers have to come up with new ideas and solutions that result in energy saving products. These products should use the correct components like up to date EC fans. Suitable materials should be selected to minimize the embodied carbon of the product itself. Last, but not least, the manufacturers’ production plants should be state of the art with regards to energy saving production facilities and renewable energy sources, similar to Kampmann‘s migration to solar electricity.

For manufactures the “Road to Net Zero” should not be a problem or challenge. It is an opportunity.