Diffusion Net Zero

Net Zero With Diffusion

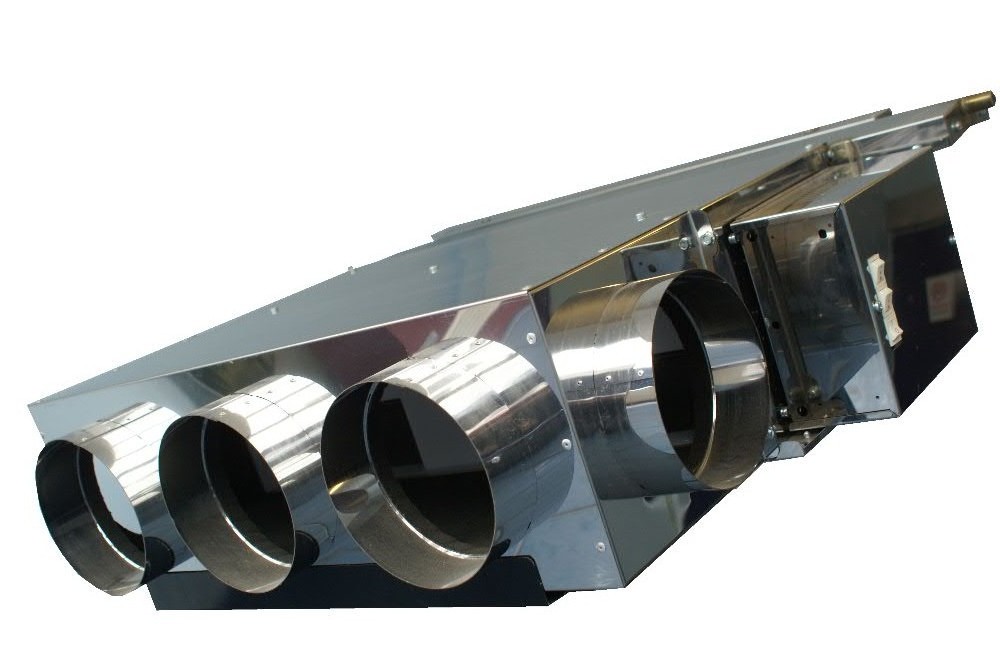

Diffusion have been the market leaders in SFPs for over 50 years. Their standard FCUs achieve SFPs as low as .15 w/l/s and some as low as .11 w/l/s.

Diffusion’s approach to Nett Zero Carbon and high efficiency, low SFP fan coil units is all inclusive. Once they make an improvement in efficiency, they incorporate that improvement into every fan coil across their standard range. They don’t make a separate model and market it as a low energy model.

Hence, Diffusion’s most standard and widely used fan coil unit, the 270ec model, is also their most efficient model, with SFPs selections available below .15 w/l/s, without oversizing the unit, and some SFP’s as low as .11 w/l/s, This has been the case since as far back as 2016.

Diffusion have been manufacturing fan coils for over 50 years, and from the start have maintained a huge commitment to R&D

Their ultra low SFP’s are the result of long term development and co-operation with their German fan manufacturers. This has led to the development of a range of fans specifically designed to match to the requirements of each size of fan coil unit and resulting in the lowest possible electrical energy used (watts) for each litre/second of air generated.

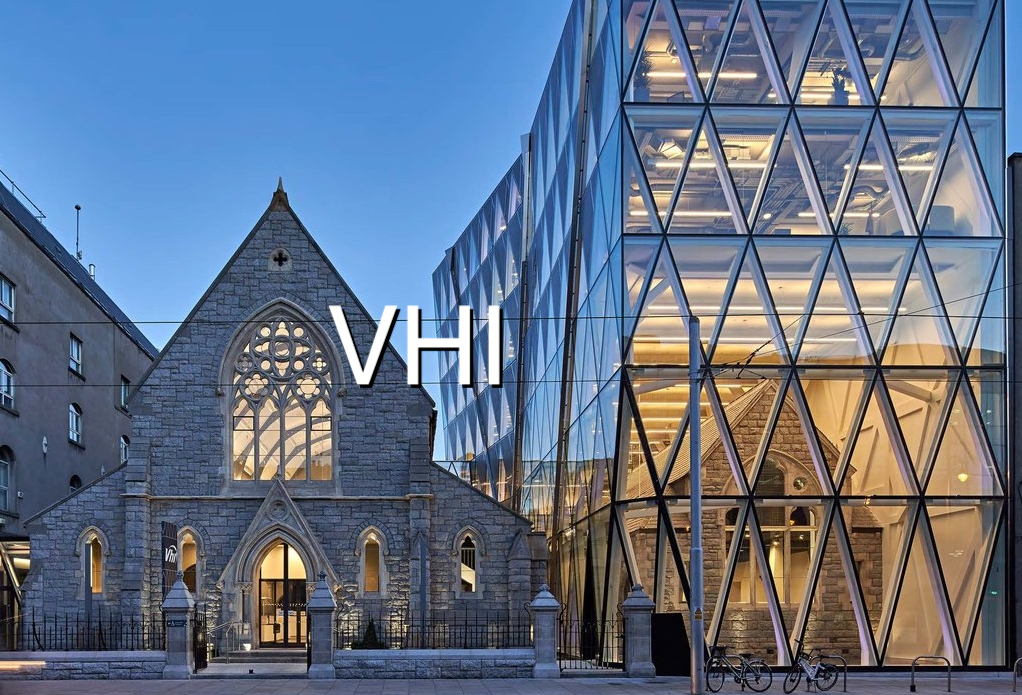

A Fan Coil Unit for Your Building

No matter what project your are working on, we have a range of energy efficient fan coils and are sure to have one that suits your needs and achieves lower carbon emissions.

Waterside Units

Airside Units

What is SFP and Why Is it Important

Specific Fan Power (SFP) is the most accurate guide to determining the electrical load and therefore running cost of operating a fan coil unit in a building. It details the watts consumed for every litre/second of air delivered by the fan coil to the room. Of course, not all system layouts are the same with regards to the size and length of ductwork, grille selection and air volumes being used, So, as is also the case with noise levels, the industry standard is to measure SFP against an external pressure of 30 Pa, which is an appropriate figure to allow for a correctly sized length of ductwork, a bend, damper and a swirl diffuser with plenum box. This is also very important when comparing the efficiency of one unit against another.

However, it is very important that design engineers insist on SFP’s being measured at an external pressure of 30Pa as, for example, an SFP value measured at 20Pa will be significantly lower, and not very practical, as one swirl diffuser grille, on its own, can generate an external pressure higher than 20Pa and you still have ductwork, bends and dampers to consider.

It is also important to beware of SFP values quoted under the heading of ‘Anticipated Installed SFP’ as you don’t know the actual external pressure that is being used to measure the value.

Contribution to LEED Certification

Low SFP values can make a significant contribution to attaining a building’s LEED certification.

It might surprise some to know that Diffusion has, since 2016, been carrying out fan coil selections, achieving SFP requirements of < .15 w/l/s, for design engineers wishing to attain certification, up to Platinum LEED standard. Diffusion have achieved these low SFP values through continuous targeted R&D in this area which was conducted in collaboration with their main fan suppliers

In-Efficiency Costs Money

When in-efficient fan coils are installed, the biggest losers are the end tenant and the environment. More energy is consumed, causing higher energy bills and a higher carbon footprint for the building.

Net Zero Carbon

While most fan coils on the market have a lifespan of approx. 15 years or more, with Diffusion it has always been their philosophy that there is no need to replace any of their FCUs ever, only their components. In that way Diffusion are avoiding the carbon impact caused by replacing the chassis, attenuation and a host of other components.

We are presently engaged with updating fans and coils on units that are over 20 and even 30 years old, upgrading them with the most efficient fans and coils that today’s technology can provide.

In the meantime, the client benefits from the true flexibility in control and comfort levels that only fan coil units can provide and the environment benefits through lower carbon generation by avoiding the manufacture of a completely new unit and through lower energy consumption by using more efficient components.