Wilton Park

Comfort and control.

One Wilton Park.

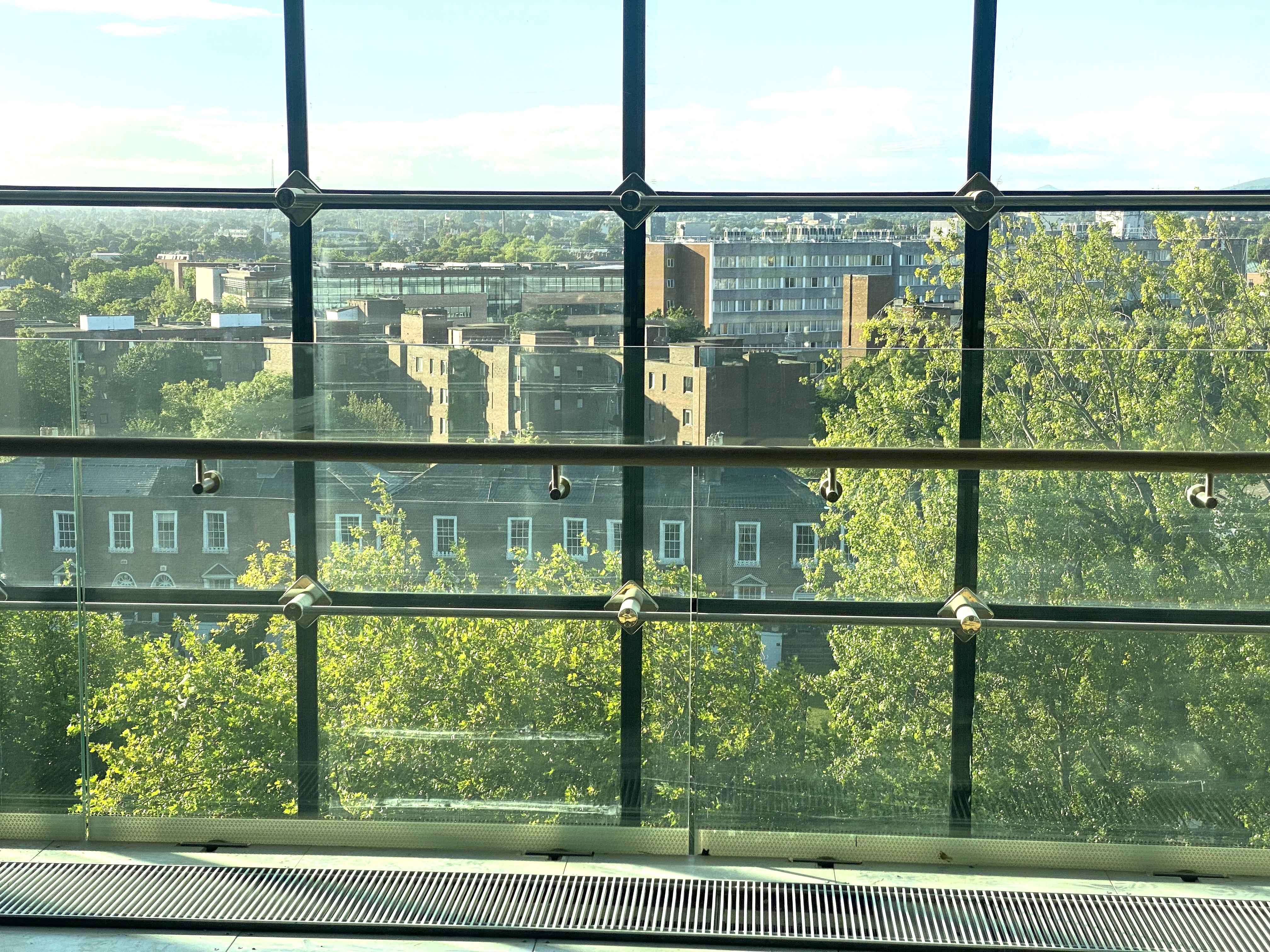

One Wilton Park was designed by architects Henry J Lyons, with connectivity in mind. The LEED Platinum, IPUT building, consists of two client blocks, to be taken over by LinkedIn as their future EMEA Headquaters, with an atrium of interconnecting sky walks at their heart, linking both together.

The design concept at One Wilton Park included two separate blocks joined together by an open glazed atrium with multiple air sources. Within the atrium are a series of interconnecting bridges which allow the end user access from one block to the other.

Bespoke Solutions

Essentially the request was to create a micro climate on the bridges at each floor level. However, the real challenge with the bridges was to ensure consistent delivery of comfortable heating and cooling with the concern that the conditioned air could spill out over the balustrade and into the atrium environment.

Kampmann used their own state-of-the-art testing facilities to undertake a CFD (Computational Fluid Diagnosis) to analyse the area, and the air flow patterns, in heating and cooling mode from the trench units to be installed in the bridge walkways and seated areas which were to be used for impromptu and casual meetings.

Through the CFD they examined exactly what would happen when the air hit against the glazed balustrade and when it was directed inwards into the space. The results of the CFD showed that as the bridge walkways were a transitional space where people would spend minimum time, the air from the units could be safely directed into the space and condition it without impacting on comfort levels. In the seated areas the air is directed towards the balustrade where it will rise vertically then bounce back above the occupants and fall gradually without causing any discomfort. Micro climate achieved!

Working with Arup (Consulting Engineers) and Leo Lynch (Engineering Contractor) Keane Environmental and Kampmann developed totally bespoke heating and cooling trench units, to suit this very special application. While all the units look the same above ground, and provide a consistent continuous appearance, they embody a huge amount of modifications below the surface.

These modifications allow them to:

- Tie in with the structural steel supports that can vary from location to location and for bridges at the different levels

- Allow the units to run in series but blow the air in different directions.

- Have different connection handings and pipe access points all while running in series with providing a continuous appearance above floor level.

As each space was different, the challenges facing each set of trench units had to be individually identified. Kampmann designed the each trench unit specifically for the space it was going into, allowing multidirectional airflows and changing the positioning of the fans and heaters within each unit. The result is that each one of the trench units installed was designed as a bespoke unit for the space it was built.

.

LOW SFPs

Trench technology is a proven solution to heat, cool and ventilate our buildings. The coils within the Kampmann units have been optimised to work with ultra-low LPHW temperatures fed by heat pumps and cooled with chilled water, for both wet and dry cooling.

All these units come with modern EC-fan technology. This allows the trench units to run at the lowest noise levels, even down beyond NR 25. In addition, modern trench units achieve Specific Fan Power levels (SFPs) in the region of 0,08 to 0,12 watts per l/s.

Questions?

At Keane Environmental Ltd., we understand that every job, large or small, has its own challenges. We’d be delighted to work with you to find the correct solution for your building. If you’d like to hear more about this or any of our other projects, contact us today.

Architect: Henry J Lyons

Consulting Engineer: Arup

Engineering Contractor: Leo Lynch

Supplier: Keane Environmental Ltd.

Recent Projects

Find out more about our other recent projects below.